About

us

Decades of experience in the manufacturing of single-dose packaging for cosmetics.

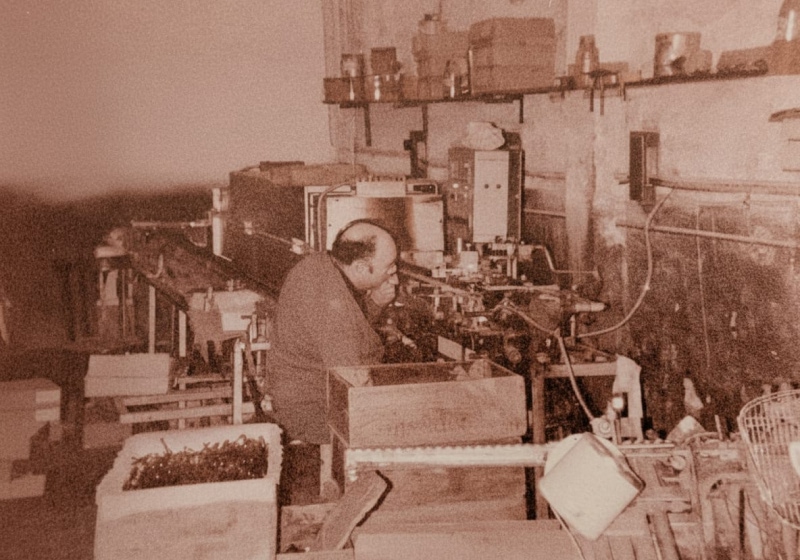

CRISMAT was founded in Barcelona at the end of the 1950s as an artisanal company dedicated to the manufacture of lamp holder caps.

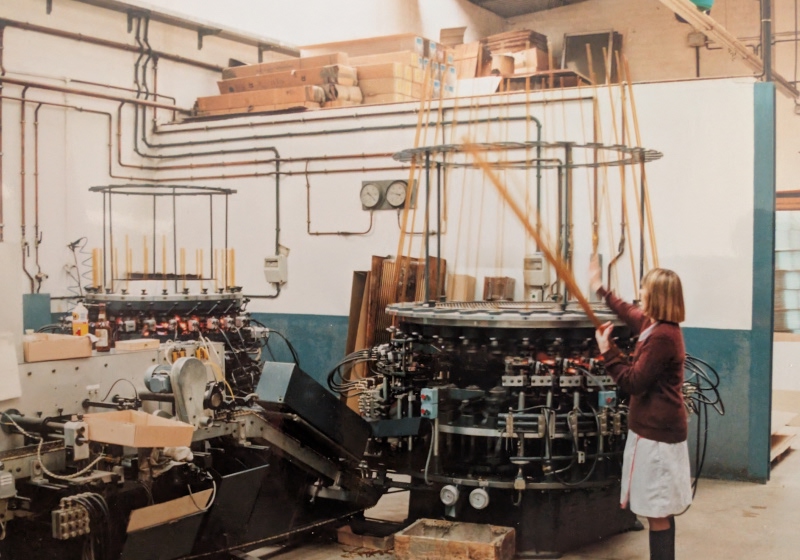

In 1989, it moved its factory to Santa Perpètua de Mogoda to larger and more suitable facilities for the new product it manufactures: single-dose glass ampoules for the Cosmetics and Pharmaceutical Industry.

In 2006, the company's first Clean Room was put into operation to comply with Health standards and improve the quality of its products.

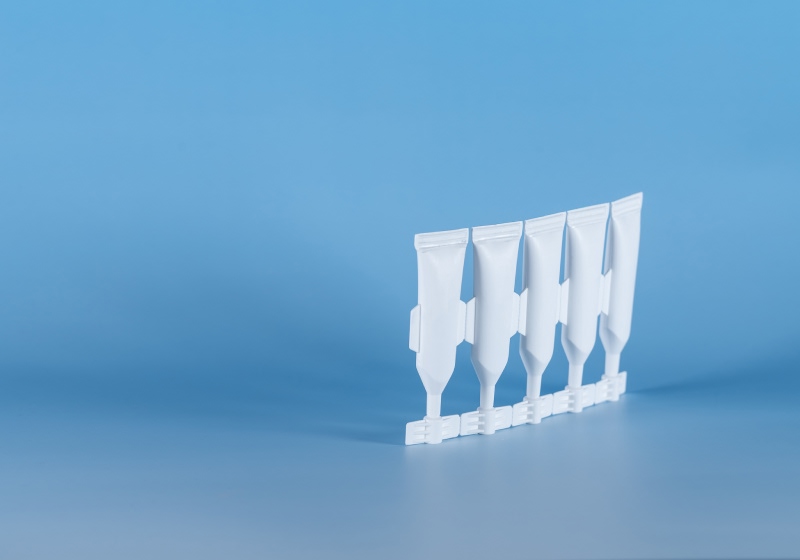

In late 2013, a new business line began operating: plastic strip packaging, which comes to complement the sector's demand.

In 2022, we expanded our facilities, inaugurating new clean rooms, allowing us to improve both quality and production capacity.

CRISMAT's rigorous quality controls include:

Wall thickness

Wall thickness measurement of the ampoule.

Breaking strength

Measurement of the breaking strength of the ampoule.

Ampoule's stress

Checking the ampoule's stress.

Ampoule's weight

Control of the ampoule's weight.

Vision control

Vision control during the manufacturing process of glass ampoules.

Microbiology analysis

We have the external support from an accredited laboratory for microbiology analysis.

Calibrated measuring

We have calibrated measuring equipment accredited by certified laboratories.

Quality certificates

In production processes, safety, effectiveness and compliance with the standards of ISO 22716 and ISO 9001 are sought.

We have a certificate of compliance with good manufacturing practices (GMP) for cosmetic products. We comply with RD 1275/2011 of the Spanish Agency for Medicines and Medical Devices.

We are committed

to sustainability

At Crismat we are committed to sustainability, which is why we have recently invested in a photovoltaic plant to provide our company with energy from sunlight. To this end, we obtained funding from the Next Generation and Technofinance funds to install 120 solar panels with a power of 545 Wp each, which provide an annual production of 93,000 KWh. This allows us to offset the emissions of over 35 TM of CO2 per year.

We are also committed to waste management, which is why we offer separate collection of glass and cardboard.